Why investment in automation technology is vital to achieve Net Zero

Utilities today face multiple pressures and an increasingly complex environment due to the expected disruptions driven by climate change, regulatory and consumer demand for a ‘greener’ power network, as well as the pressure to deliver on a variety of Net Zero commitments. The accelerating electrification of transport, heat and industry, together with the needs of emerging novel technology solutions, such as hydrolysis or carbon capture and storage, will put additional pressure on their operations. The recent international developments have also highlighted the imminent need to move away from the dependence on global oil and gas markets, to ensure continuity of supply.

Utilities will be central in achieving Net Zero, playing a crucial role in a multitude of aspects, including energy storage, energy supply optimisation, integration of renewables and more.

While these issues are key for developing a flexible network to meet future needs, utilities have to navigate the challenges while maintaining the smooth running of their networks, keeping end-user costs relatively stable, as well as preparing for vulnerabilities, such as potential cyber-attacks. A fine balance.

Automation as part of the solution

According to estimates from the recent report by BEAMA & Energy Systems Catapult titled ‘Growing the Supply Chain for a Net Zero Energy System’, electricity demand could grow by 70% by 2050. The report also highlights the need for more coordination and planning between utilities to respond to this forecast growth. Flexible systems will be an absolute key, and these can’t be developed without digitalisation and/or automation on a much wider scale.

It will be imperative for utilities to stay in control of their systems and monitor them in real time. Automation technologies are designed to do just that, as well as alleviate the immediate pressures on network management.

One of the hurdles to overcome in maintaining control over their networks is the increase of ‘prosumer’ households, where solar panels or other installed energy generation devices are selling electricity back to the network, rather than just consuming it. The integration of renewables and low carbon technologies is growing by the day, such as the rapid expansion of electric vehicle fleets. These changes will unavoidably disrupt the traditional one-way direction of electricity distribution, to be replaced with a two-way flow and more complex patterns of demand. These factors require significant changes and an increased engagement with automation on the utilities’ side.

Products and services allowing automation of processes and digitalisation that can provide much needed support in dealing with this two-way flow already exist and can be implemented at relatively short notice.

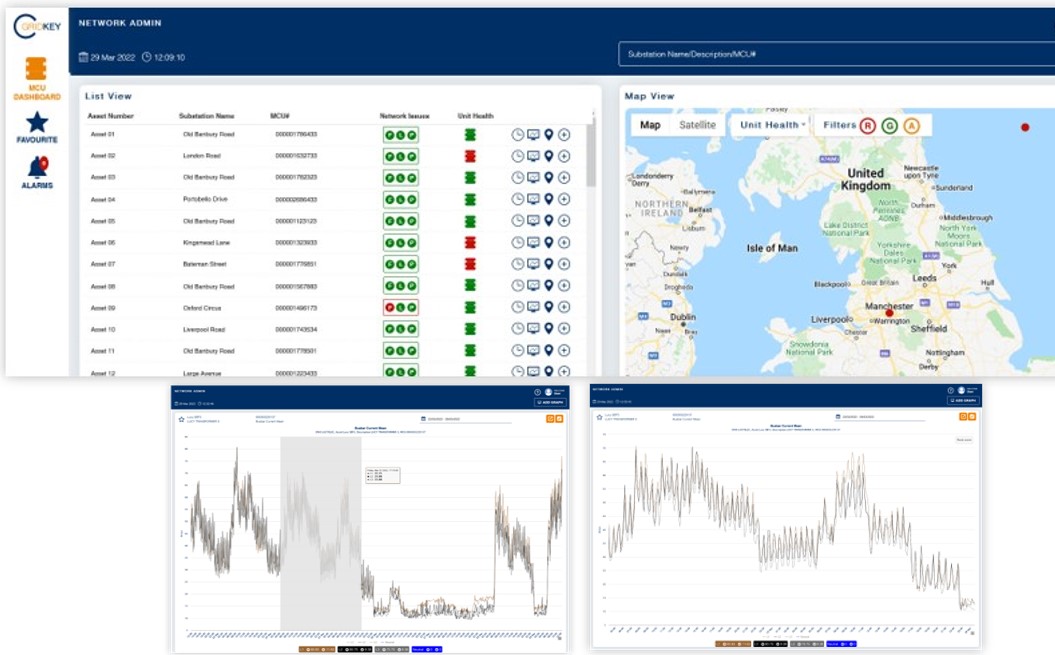

A resilient and reliable network is expected, but these can only run smoothly by relying on accurate data in real time. Automation solutions, such as Active Network Management, can enable real-time monitoring and control over generation, transmission, distribution as well as outage management, in addition to resource optimisation across the whole power enterprise. Data needs to be available for engineers both at desks and on-the-go, to enable a timely reaction, and also to allow improved planning capabilities.

Automation technologies facilitate flexibility and a more accurate match of supply and demand, improving efficiency both in terms of resources and costs. Utilities can rely on such solutions to utilise their latent capacity better, eventually opening up their network to a larger ratio of variable renewable sources, but without major capacity investment.

These technologies are also ideal to work on microgrids, which provide self-sufficient energy production and distribution at a local or regional level. Such grids generally comprise of diverse sources of electricity, including solar, wind, hydrogen power and advanced battery storage technologies.

On a broader scale, the creation of ‘digital twins’ of physical production facilities could be an ideal tool to understand the impact of potential adaptations before such changes are implemented.

Why invest in automation now

For maximum cost efficiency, early investment generally leads to better outcomes. This is the same in the case of automation technologies, where early integration can pay off in the long-term, especially in an industry where a significant level of disruption is almost certain.

Today’s existing technologies are already extremely versatile, allowing for new installations as well as retrofitting existing networks, and can be installed in a variety of geographies, including remote areas, to meet local needs.

Given the rise for demand in electricity across all walks of life, from heating homes to transport and industrial production – and with the additional power coming from smaller, disparate suppliers – automation of the processes and systems underpinning the industry is the only way these challenges can realistically be met.